ARCHIPELAGO TECHNOLOGY: inkjet innovation that could revolutionise the way viscous liquids are dispensed

On an innovation centre in the heart of Cambridge, a small yet highly-experienced team of engineers are busy creating ‘the next big thing in inkjet technology’ that will revolutionise how coatings are applied.

Guy Newcombe, chief executive of Archipelago Technology

Coatings are everywhere – our cars, homes, gadgets, and even the food we eat. Yet the spraying process used to apply these coatings is often expensive and inefficient, with up to 50 per cent of the applied substances wasted.

The Cambridge team at Archipelago Technology wants to replace the spraying process with a versatile inkjet alternative that overcomes the problems of existing approaches, lowering costs and reducing waste.

“We believe our technology will revolutionise the world of inkjet technology, enabling low waste coating of difficult materials,” says Guy Newcombe, chief executive of Archipelago Technology.

“The global inkjet market is worth many billions of dollars. And we feel our technology could find applications across multiple applications.”

Innovation in action

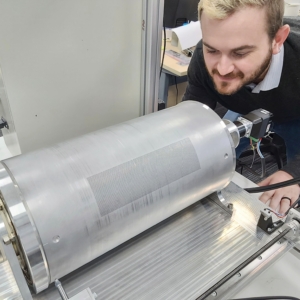

At the core of the company’s Powerdrop process is a drum with a collection of precise nozzles built into a hollow cylinder.

The Powerdrop process uses a drum with a collection of precise nozzles built into a hollow cylinder.

The coating material is loaded into the nozzles from the outside of the drum using the Powerdrop filler. The drum rotates, and the coating material is jetted out as drops using the Powerdrop blower component. The jetted drops of coating material fly through the air to land on the surface and stay there. Waste, drift and overspray are very low.

“It is a non-contact process that can operate at high speed and handle even difficult materials such as high viscosity adhesives,” says Guy Newcombe, who has more than 30 years’ experience in inkjet at industry-leading technology companies like Domino and TTP. “It can apply high quality, water-based coatings with minimal waste, making it suitable for even high-value materials. The system delivers precision doses of materials at distances of 300mm or more, yet with millimetre accuracy.”

These technical characteristics make Powerdrop ideal for various industrial uses, such as applying coatings and adhesives in the furniture and packaging sectors and crop spraying in agriculture. “These are multi-billion-dollar industries, so the potential for the technology is huge,” says Guy Newcombe.

Scaling the business

Archipelago has sold its first bespoke machines to customers in recent months, produced from a core set of component parts. The plan now is to close an additional funding round by the end of the year and start scaling production. The challenge moving forward, says Guy Newcombe, is remaining focused and identifying core markets. “Powerdrop is so versatile and adaptable that there is a temptation to chase every opportunity. We must be careful to concentrate our resources on areas with the most potential.”

Another challenge is finding the right blend of skills. At present, Archipelago has around a dozen employees – primarily engineers. But as the company scales, it will need new people from different backgrounds. “Up until now, our efforts have been focused on research and development. But as we move towards commercialisation, we will need to add resources in areas such as sales and business development. So, we must attract the right people and ensure they are fully empowered to work together as a team.”

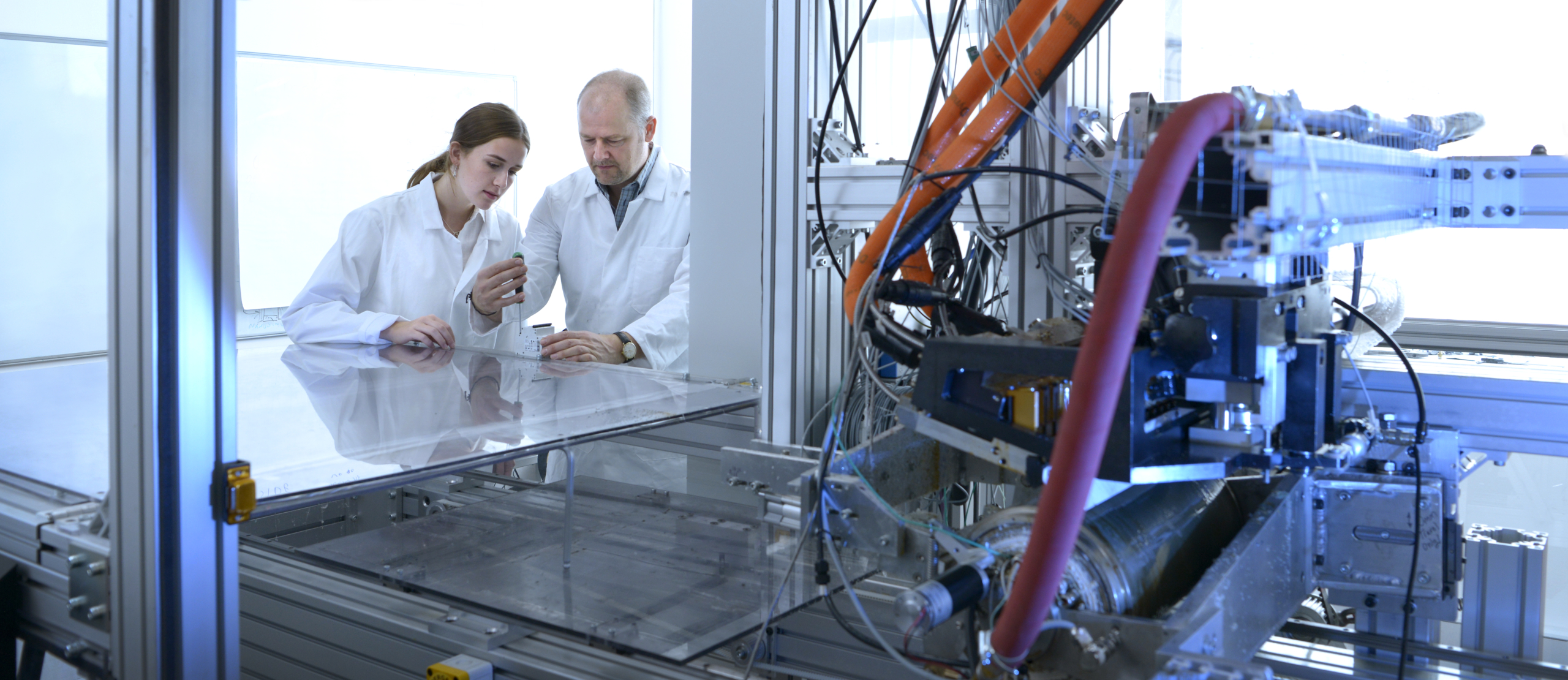

Research and development activities at Archipelago Technology

Guy Newcombe has his work cut out, then. But he isn’t fazed by the enormity of the task ahead. “There is nothing I don’t enjoy about running a technology business,” he says with a smile. “I like talking and listening to other people, and I enjoy the challenge of designing and building big machines.

“In terms of advice to other entrepreneurs, you should always surround yourself with critical friends. I value the input of colleagues on the board – I make sure they are not just people who agree with me all the time.”

Why networking matters

Networking is another way Guy Newcombe ensures he gets sage advice from his peers.

For several years, Archipelago has strongly supported the Bessemer Society – a forum for serial CEOs, company founders and entrepreneurs in hard-tech sectors.

The Society runs networking events across the country with high-profile speakers from various backgrounds.

“I have been involved with the Bessemer Society since its inception, and it represents an opportunity to meet with peers and learn from their experiences,” he says. “The networking sessions focus on key areas such as funding, governance and innovation – and they are always fascinating.

I get a lot out of being a member of the Bessemer Society and would recommend it to other individuals who are building technology companies.”